Products

Chemical

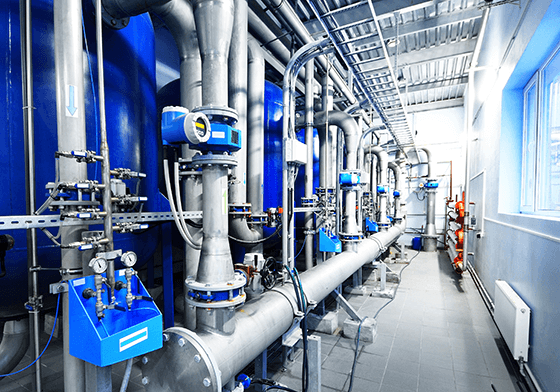

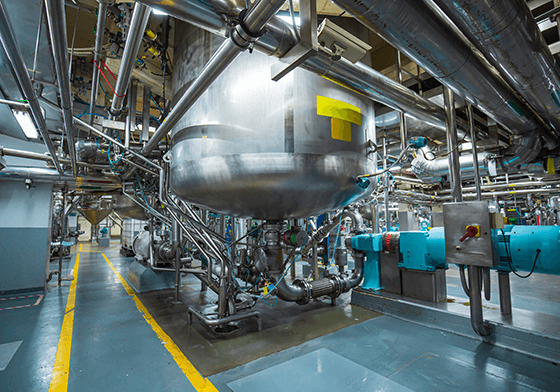

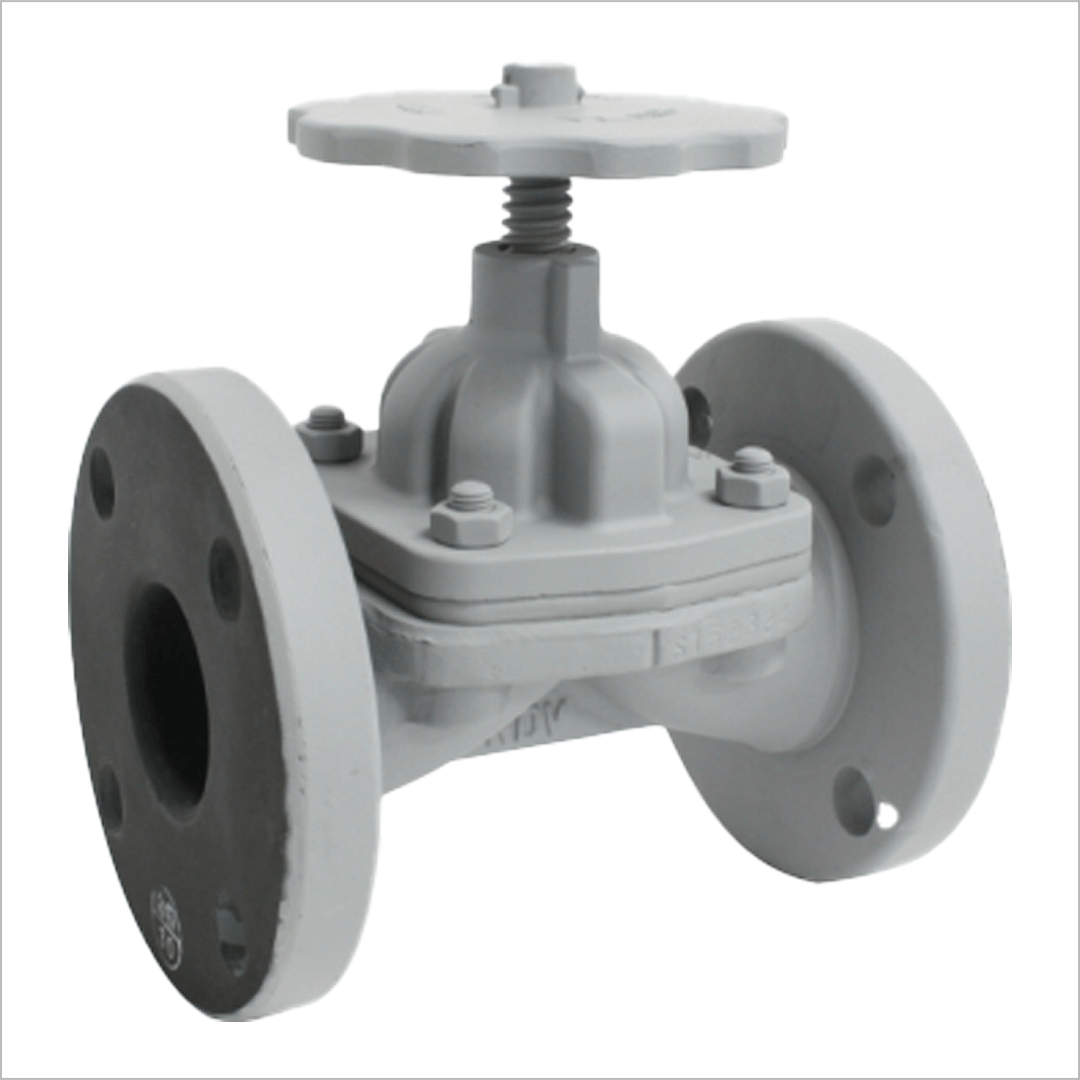

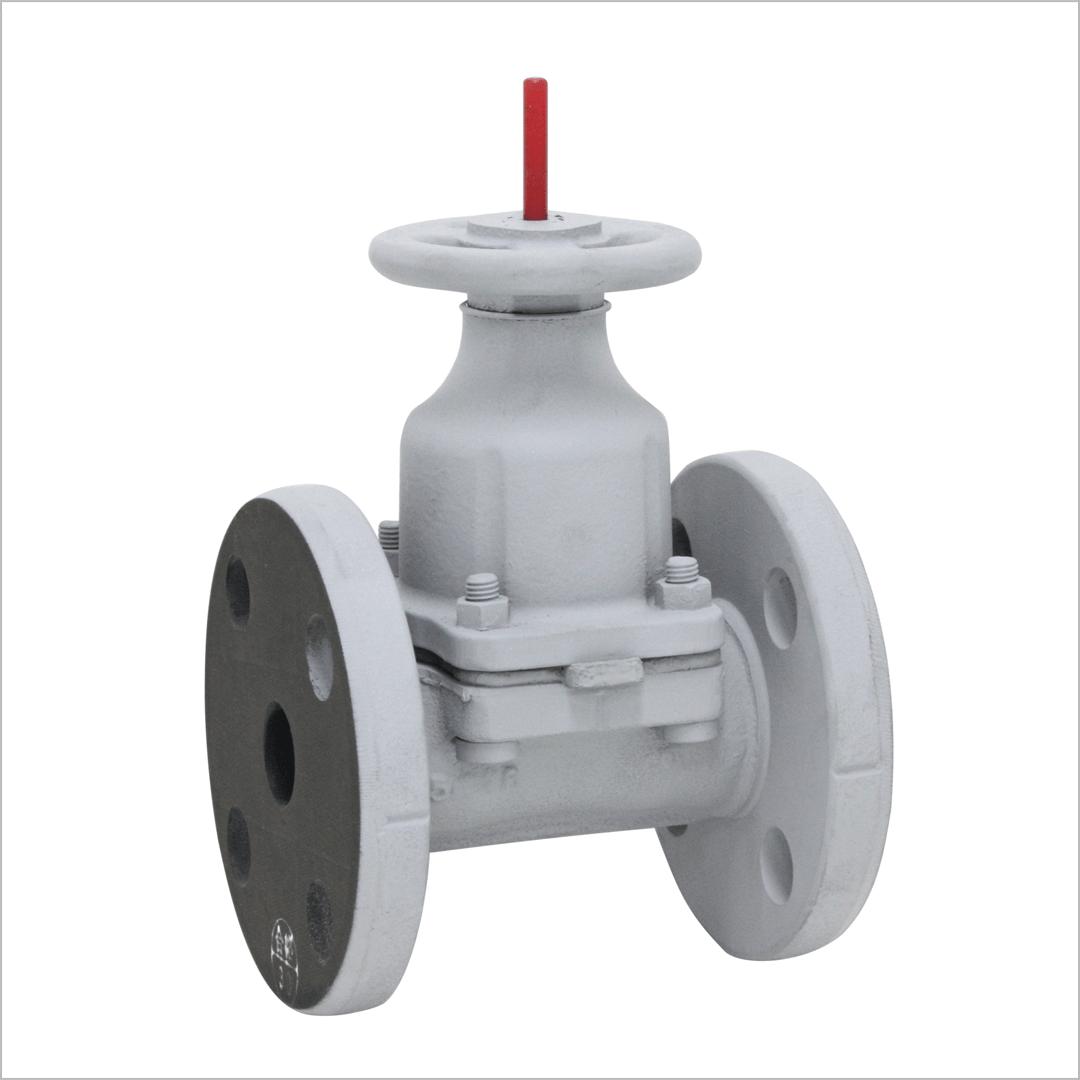

We have an extensive track record in domestic and overseas chemical plants. It has been accepted in a wide range of fields for many years with maximizing the features of the diaphragm valve, including a pocketless structure without liquid pools, and airtightness, cleanability, maintainability, and corrosion and chemical resistance.

The combination of wetted parts materials enables the application to various conditions of use, such as liquids, gases, strong acids, and alkalis.

Applications (Chemical Industry)

Examples of applications and equipment

Electrolysis plants, treated water lines and various process fluids.

Selection example

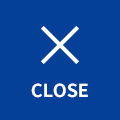

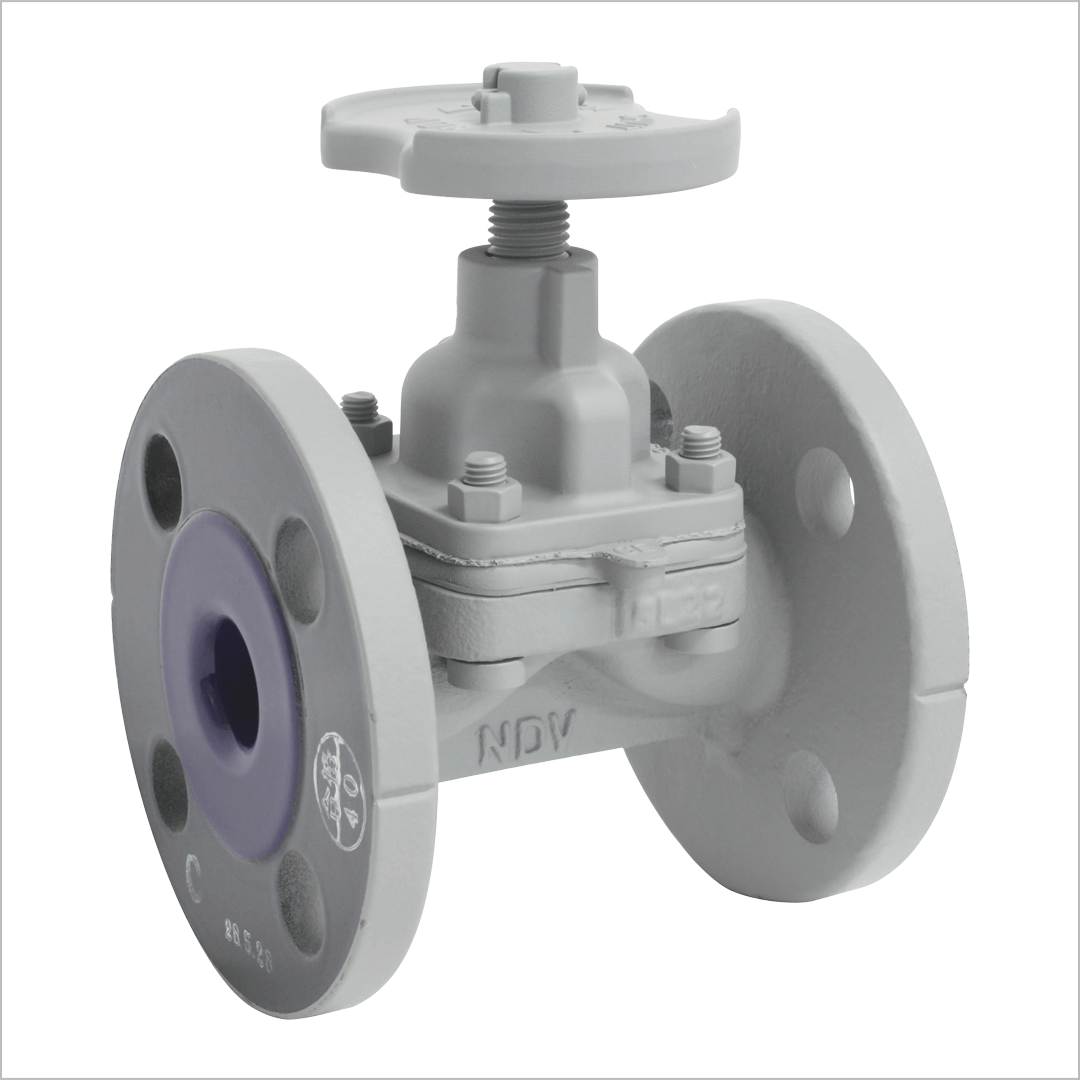

Rubber lined body

-

Weir type (400 type)

-

Straight type

(500 type)

Examples of applications and equipment

Electrolysis plants, ethylene plants, fertilizer plants, melting processing facilities, strong acid lines, strong alkali lines, and various process fluids

Selection example

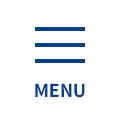

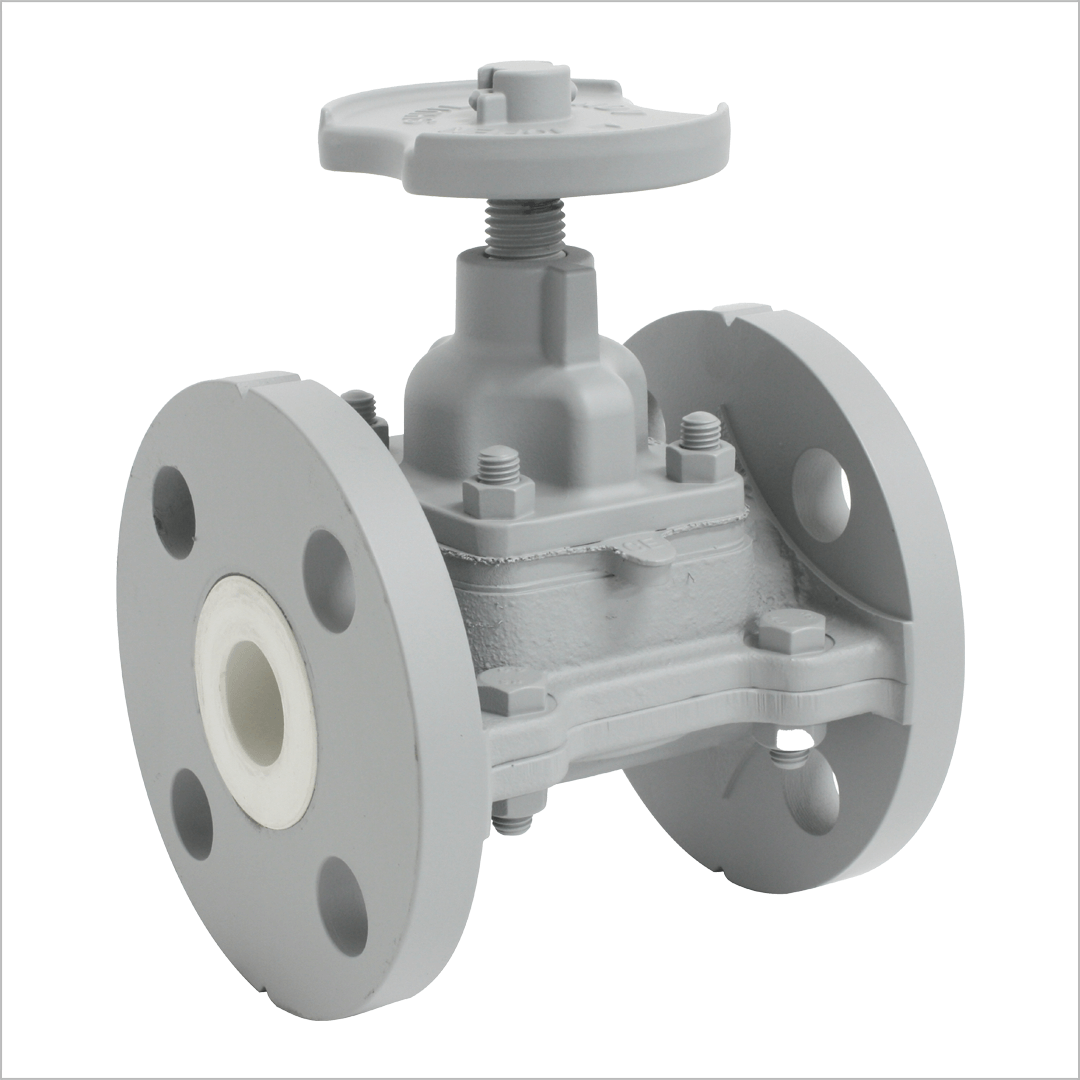

Fluorocarbon resin lined body

Examples of applications and equipment

Strong acid line, various process fluids

Selection example

Glass lined body, porcelain lined body

Examples of applications and equipment

Bioethanol facilities, treated water lines, saturated steam line and various process fluids

Selection example

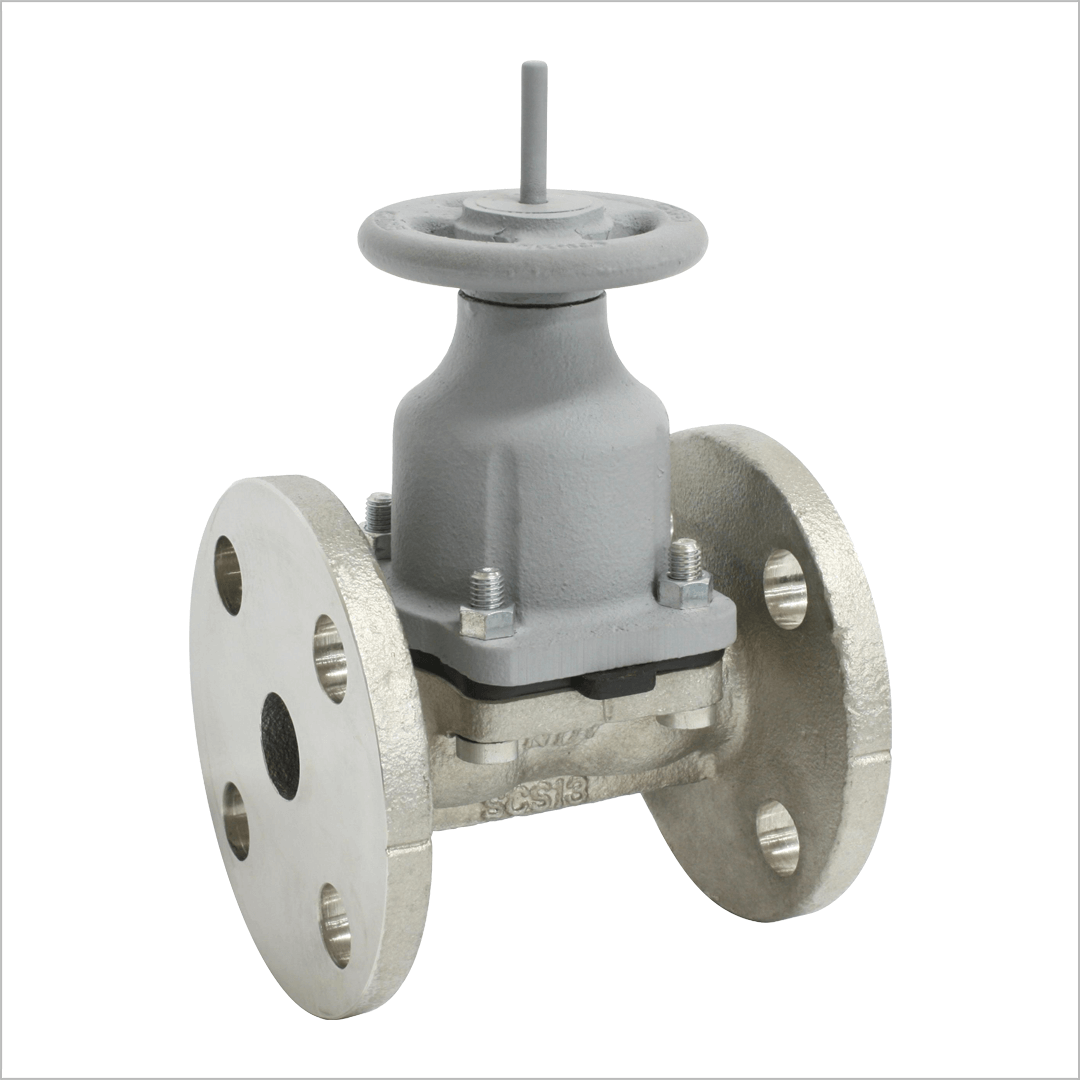

Stainless steel body

-

Weir type (400 type)

-

Straight type

(500 type)

- This information is an example of usage. The combination of body and diaphragm material may differ depending on the actual fluid conditions.

- Diaphragm valves have the advantage of being able to select the optimum and economical product specifications according to the fluid. Please contact our sales representatives for enquiry.

Related Information

Data Download

Inquiries about this information

For the production specifications, please click here

(Please feel free to contact us if you have any questions or

any other products which are not described here.)